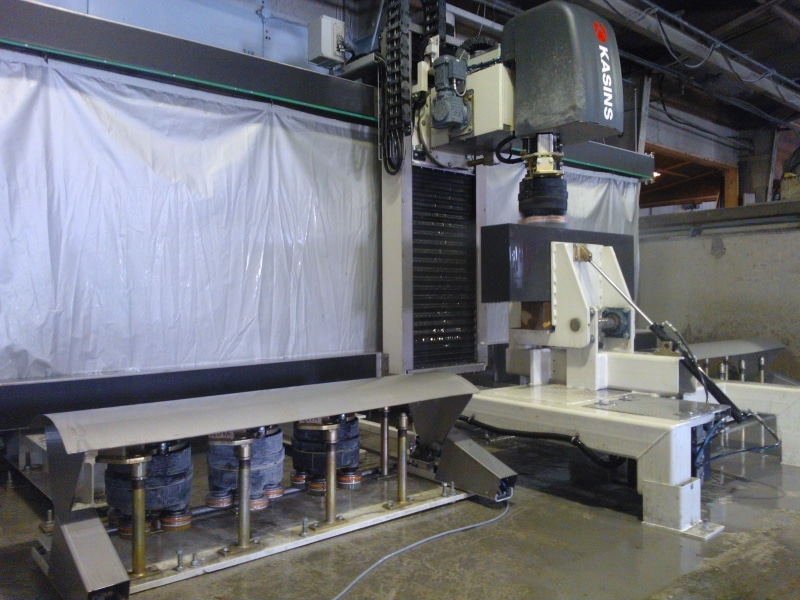

Buffalo automatic edge polishing machine

Three edges can be polished automatically. In the magazine is room for eight heads.

If necessary, more than one stone holders can be used.

Solid, vibration free construction ensures high quality polishing results. The special constructional demands characteristic for stone machinery, have been carefully taken into consideration already at the planning stage. Especially guides, bearings, guards and corrosion protection have been precedence. All the mechanical solutions are stated good at practice.

The controls, functions and operating itself has been developed together with the professional workers in the stone industry. This means that interface etc. are very easy to use and the user’s point of view has been expressed in that all the way!

The graphic display on the control panel shows very clear and illustrative. Therefore the information is extremely easy to set and read. The important parameters will not be forgotten by the operator.

Technical data

- Spindle speed 450 r/min

- Polishing head Comes TL104 diam 320 mm

- No of abrasives 4 kpl

- Abrasive diam. 100 mm

- Spindle power 5.5 kW

- Adjustable pressure(down) 0...6 bar

- Adjustable pressure(top) 0...6 bar

- Spindle stroke(pneumatic) 100 mm

- Vertical movement 1460 mm

- Vertical movement guides linear ball rail

- Carriage movement as standard 5100 mm

- Carriage speed 1...9 m/min

- Carriage movement guides linear ball rail

- Carriage movement tooth bar

- Oscillation 0 ... 150 mm, electric

- Grinding length as standard 2000 mm

- Head turning ± 90 deg.

- Total weight n. 5000 kg

- Power requirement 10 kW

- Water consumption 20 ltr/min

- Air pressure 6 bar

Space requirements:

- width 6200 mm

- length 3000 mm

- height 3050 mm