Products

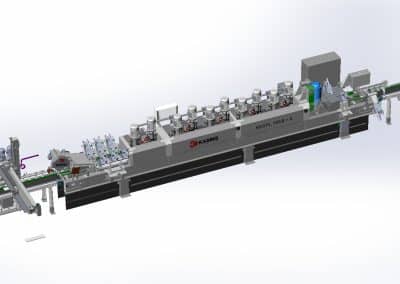

Tukeva ja värinätön rakenne yhdessä jouhevien liikkeiden kanssa takaavat erinomaisen hionnan laadun. Korkeatasoinen automatiikka vastaa kaikkia tämän päivän vaatimuksia tasohionnassa. Joustavuus tuotannossa on merkittävä asia tämän päivän yritysten tuottavuudessa.

The flexibility in the production is remarcable benefit in todays companies!

Hohe Flexibilität in der Produktion ist bemerkenswerter Vorteil auf dem Markt von heute!

Luotettavuus ja tuottavuus ovat avainasioita tämän päivän kivenjalostajille!

Zuverlässigkeit und Produktivität sind zentrale Themen in der heutigen Steinbearbeitungsunternehmen!

Koneet on suunniteltu pitkäikäisiksi, kestäviksi kokonaisuuksiksi ja kovia rasituksia kestäviksi jatkuvassa käytössä. Kasins katkaisusahojen ja -linjojen automatiikka on monipuolinen, ja vastaa vaativankin käyttäjän tarpeita.

Käyttöliittymä on selkeä ja helppokäyttöinen.

Sahat voidaan varustaa erityyppisillä syöttö-ja poistokuljettimilla sekä mittavasteilla sahaustapahtuman automaatiotasosta riippuen.

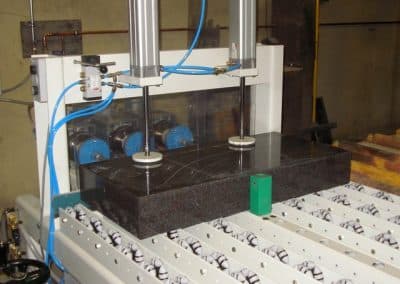

Sahat on huolellisesti suunniteltu ja toteutettu nimenomaan graniitin työstöön.

Tukeva rakenne, tarkat ja kestävät johderatkaisut, automaattiset valvonnat ja muut ominaisuudet takaavat ja huipputarkan ja laadultaan erinomaisen sahausjäljen erittäin korkealla sahauskapasiteetilla!

Sahatun pinnan korkea laatu tuo merkittäviä kustannussäästöjä myöhemmissä työvaiheissa kuten esim. hionnassa.

Kasins Block saws are reliable and economical saws, both in investment and operation costs.

The better surface you will have after the first cut, the cheaper costs you will have in finishing.

Neben ihrer bewährten Zuverlässigkeit zeichnen sich die Blocksägen von Kasins durch äußerst günstige Investitions- und Betriebskosten aus.

Je besser die Oberfläche ist, die Sie nach dem ersten Schnitt erzielen, desto weniger kostet die Fertigbearbeitung.

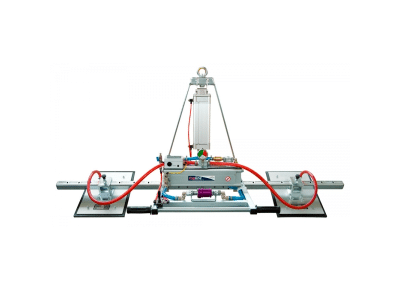

Kasins myy, asentaa ja huoltaa ScandInventin koneet. Koulutuksen ja tuotetuen saa meiltä suomeksi.

Please see the website of Scandinvent AB: www.scandinvent.com

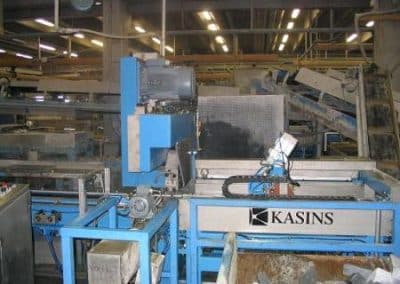

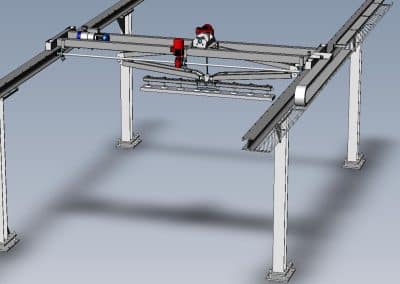

Kasins Oy on toteuttanut lukuisia yksilöllisiä tuotantokoneita ja –kokonaisratkaisuja asiakkailleen. Innovatiivisuuden ja kokemuksen yhdistäminen sekä kokonaisvaltainen sitoutuminen asiakkaidemme erilaisiin tarpeisiin ovat avainasemassa erikoiskoneiden suunnittelussa ja toteutuksessa.

Yksilölliset kone- ja laiteratkaisut syntyvät aina tiiviissä yhteistyössä asiakkaidemme kanssa.

Te tiedätte tarpeet ja tavoitteet – me toteutamme ne!

Kasins Oy has designed and built several individual machinery and production lines for our customer.

Whenever speaking about special machinery, we will carry out the whole process in close co-operation together with the customer!

"You know what you need, we can make it!"

Kasins Oy plant und baut auch individuelle Maschinen und Produktionsanlagen.

Spezialmaschinen werden von Kasins Oy immer in enger Zusammenarbeit mit dem kunden entwickelt und gefertigt!

"Sie wissen, was sie wollen. Wir bauen es für Sie!"

Wenn die Liste leer ist, ist momentan keine Maschine verfügbar.

Für alle angezeigten Maschinen gilt - Zwischenverkauf vorbehalten!

Ei tuotteita

Tässä kategoriassa ei tällä hetkellä ole tuotteita.

No products

There are currently no products in this category.

Keine Produkte

Derzeit gibt es in dieser Kategorie keine Produkte.

Ei osumia

Hakemaasi tekstiä ei löytynyt.

Not found

No matches for the text you were looking for.

Nicht gefunden

Keine Übereinstimmungen für den gesuchten Text.

Tukeva ja värinätön rakenne yhdessä jouhevien liikkeiden kanssa takaavat erinomaisen hionnan laadun. Korkeatasoinen automatiikka vastaa kaikkia tämän päivän vaatimuksia tasohionnassa. Joustavuus tuotannossa on merkittävä asia tämän päivän yritysten tuottavuudessa.

The flexibility in the production is remarcable benefit in todays companies!

Hohe Flexibilität in der Produktion ist bemerkenswerter Vorteil auf dem Markt von heute!

Luotettavuus ja tuottavuus ovat avainasioita tämän päivän kivenjalostajille!

Zuverlässigkeit und Produktivität sind zentrale Themen in der heutigen Steinbearbeitungsunternehmen!

Koneet on suunniteltu pitkäikäisiksi, kestäviksi kokonaisuuksiksi ja kovia rasituksia kestäviksi jatkuvassa käytössä. Kasins katkaisusahojen ja -linjojen automatiikka on monipuolinen, ja vastaa vaativankin käyttäjän tarpeita.

Käyttöliittymä on selkeä ja helppokäyttöinen.

Sahat voidaan varustaa erityyppisillä syöttö-ja poistokuljettimilla sekä mittavasteilla sahaustapahtuman automaatiotasosta riippuen.

Sahat on huolellisesti suunniteltu ja toteutettu nimenomaan graniitin työstöön.

Tukeva rakenne, tarkat ja kestävät johderatkaisut, automaattiset valvonnat ja muut ominaisuudet takaavat ja huipputarkan ja laadultaan erinomaisen sahausjäljen erittäin korkealla sahauskapasiteetilla!

Sahatun pinnan korkea laatu tuo merkittäviä kustannussäästöjä myöhemmissä työvaiheissa kuten esim. hionnassa.

Kasins Block saws are reliable and economical saws, both in investment and operation costs.

The better surface you will have after the first cut, the cheaper costs you will have in finishing.

Neben ihrer bewährten Zuverlässigkeit zeichnen sich die Blocksägen von Kasins durch äußerst günstige Investitions- und Betriebskosten aus.

Je besser die Oberfläche ist, die Sie nach dem ersten Schnitt erzielen, desto weniger kostet die Fertigbearbeitung.

Kasins myy, asentaa ja huoltaa ScandInventin koneet. Koulutuksen ja tuotetuen saa meiltä suomeksi.

Please see the website of Scandinvent AB: www.scandinvent.com

Kasins Oy on toteuttanut lukuisia yksilöllisiä tuotantokoneita ja –kokonaisratkaisuja asiakkailleen. Innovatiivisuuden ja kokemuksen yhdistäminen sekä kokonaisvaltainen sitoutuminen asiakkaidemme erilaisiin tarpeisiin ovat avainasemassa erikoiskoneiden suunnittelussa ja toteutuksessa.

Yksilölliset kone- ja laiteratkaisut syntyvät aina tiiviissä yhteistyössä asiakkaidemme kanssa.

Te tiedätte tarpeet ja tavoitteet – me toteutamme ne!

Kasins Oy has designed and built several individual machinery and production lines for our customer.

Whenever speaking about special machinery, we will carry out the whole process in close co-operation together with the customer!

"You know what you need, we can make it!"

Kasins Oy plant und baut auch individuelle Maschinen und Produktionsanlagen.

Spezialmaschinen werden von Kasins Oy immer in enger Zusammenarbeit mit dem kunden entwickelt und gefertigt!

"Sie wissen, was sie wollen. Wir bauen es für Sie!"

Wenn die Liste leer ist, ist momentan keine Maschine verfügbar.

Für alle angezeigten Maschinen gilt - Zwischenverkauf vorbehalten!

Ei tuotteita

Tässä kategoriassa ei tällä hetkellä ole tuotteita.

No products

There are currently no products in this category.

Keine Produkte

Derzeit gibt es in dieser Kategorie keine Produkte.

Ei osumia

Hakemaasi tekstiä ei löytynyt.

Not found

No matches for the text you were looking for.

Nicht gefunden

Keine Übereinstimmungen für den gesuchten Text.